How To Use Direct To Film Printers

Direct to film (DTF) printing is a versatile way to create durable, full‑colour transfers that work on cotton, poly, blends, and more, making it ideal for new and growing decorated clothing businesses in the UK. When you’re following the right press instructions, time, and temperature settings, you can achieve consistent results and unlock new product lines, from branded workwear to on‑demand fashion.

1. Place a sheet of DTF paper with the print face up on the platen of the printer, we recommend the Epson SC-F2100. Use tape to hold paper in place.

2. Using the recommended settings on the garment creator, send your design to print.

3. Once printed, carefully take the film sheet off the printer. Transfer to a tray of DTF hotmelt powder and coat the design evenly. We recommend flicking the film to remove any excess powder.

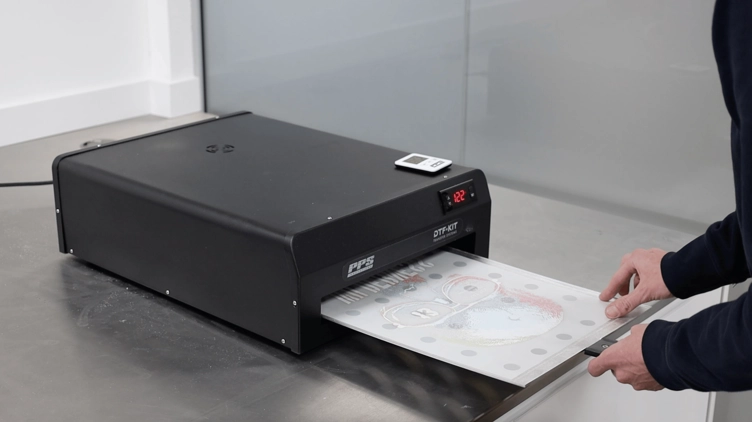

4. Using a DTF cure oven or a tunnel oven, cure the hotmelt powder until it melts and has an orange peel effect appearance. On average, this takes around 3-4 minutes at 150–160°C, depending on the powder and machine.

5. Pre-press the garment to remove any moisture and creases from the fabric. Position the film with the melted glue side down on the garment, cover with a silicone sheet with medium pressure, then press for the recommended time.

6. Once pressed, remove the garment from the heat press and peel cold.

7. Return the garment to the heat press, cover with the silicone sheet and re-press the garment for the time recommended. Your DTF print is now complete.

Recommended Time And Temperature For DTF

DTF settings can change depending on your film, ink, powder, and garment, so use these as a simple starting guide rather than fixed rules.

When curing DTF powder in an oven, aim for around 2–3 minutes at roughly 150–160°C, or until the glue has melted evenly and has a smooth, orange‑peel look.

When pressing DTF transfers, a common setting is 150–160°C for 10–15 seconds with medium pressure, increasing the temperature slightly for heavier cotton garments and always doing a quick test press first.

If you want the best results possible, check the technical data sheets that come with your DTF products and run test prints before moving to full production cycles.

Are you new to DTF printing? Check out our 10 Secrets To Great DTF Printing.

Our recommended DTF products

For a reliable, end‑to‑end setup, we offer a DTF bundle built around the Epson SureColor SC‑F2200, which gives you a professional foundation for printing and pressing transfers at scale.

Pairing this with a dedicated DTF cure oven, compatible A3 DTF film sheets and hot melt powder ensures your prints cure evenly and bond cleanly to the garment for long‑lasting results.